Chemical Batch Weighing

- Up to 10 mg accuracy for small chemicals

- FIFO (First In First Out) with J-type SS-304 dual bin structure

- Powered by ProdNX platform

- Barcode-based closed-loop filling mode

- Multiple formulas / recipes with SQL record database

- Multiple levels of security with password protection

- Bin storage capacity designed to suit raw material bag size

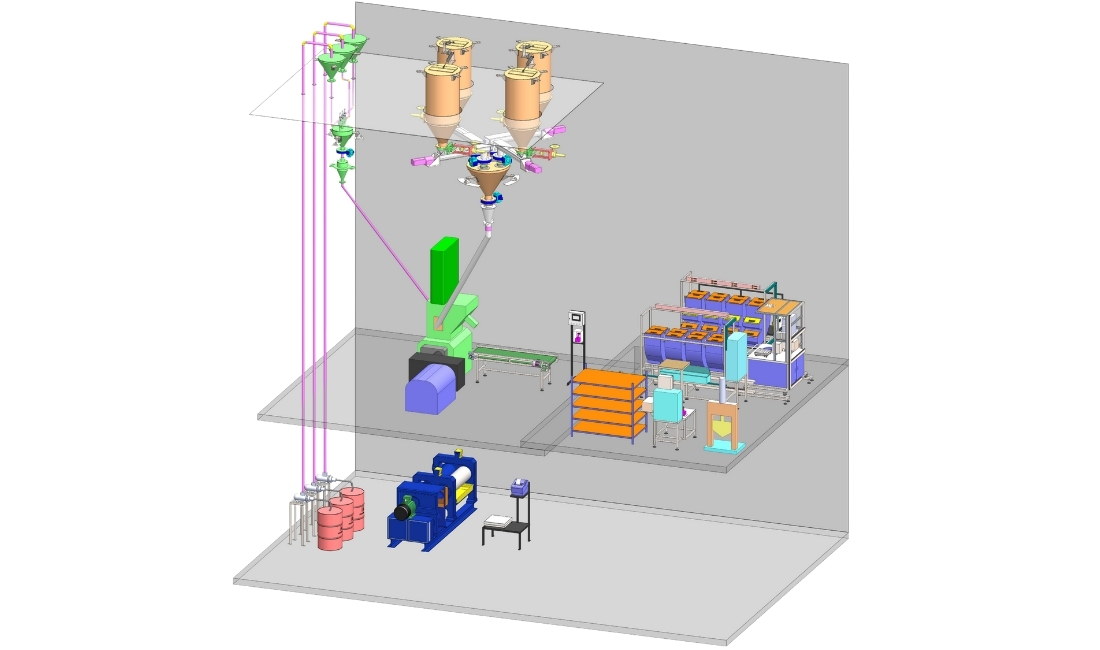

Polymer Weighing

- Accuracy up to 50 gm

- Take-off conveyor, checkweigher conveyor, and feeding conveyor as per desired dimensions

- Feeding conveyor compatible for use with checkweigher conveyor system as well as standalone weighing system

- Centralized control and reporting with scheduling

- Storage rack with magnetically locked in/out doors

Kneader/Intermix Automation

- Recipe-based formulation

- Multiple mixing stages to ensure proper mixing as per recipe

- RPM control with chamber temperature control and analysis

- Batch scheduling managed centrally

- Mixing sequence control for the mixer

- Automatic weighing and dispensing of oil, rubber, and carbon

- Mixing time, temperature, RPM, and energy parameters used to control the mixing cycle

- Capable of handling multiple oils, carbon, fillers, polymers, master batches, and more

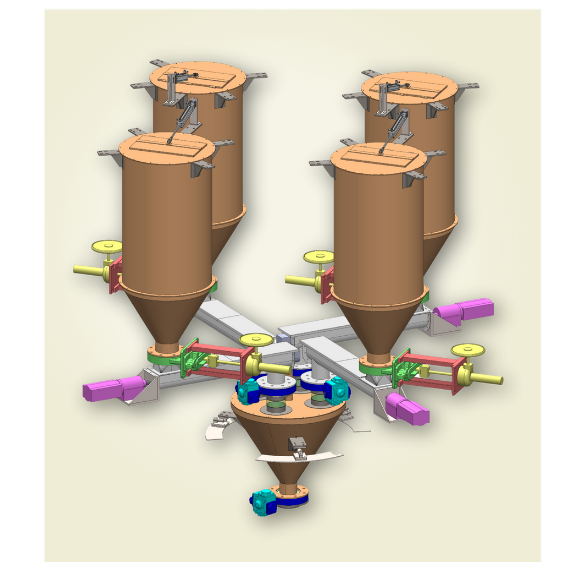

Carbon Weighing

- Variable speed screw-based precise carbon and filler conveying

- Accuracy up to 10 gm

- Centralized control and reporting with scheduling

- System compatible for use with 50 kg bags as well as jumbo bags

- Auto charging and sequencing for faster processing

- Customized design to ensure batch time and productivity within system capacity

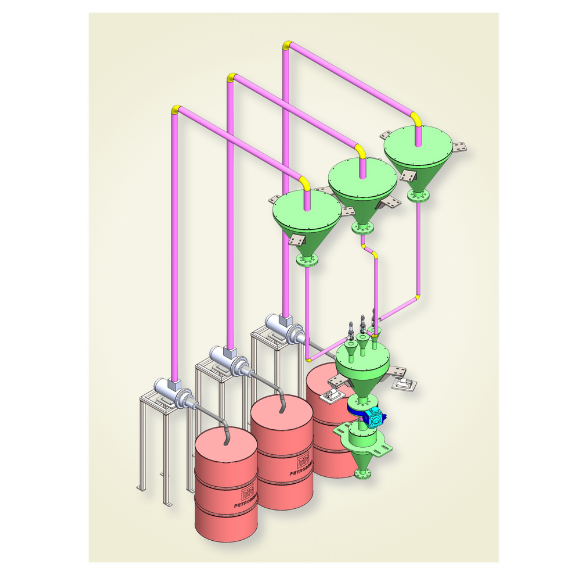

Oil Weighing

- Auto dosing and sequencing for faster processing

- Accuracy up to ±10 mg

- Centralized control and reporting with scheduling

- Heating provision for highly viscous oils

- Supports multi-oil injection with minimal cross-contamination

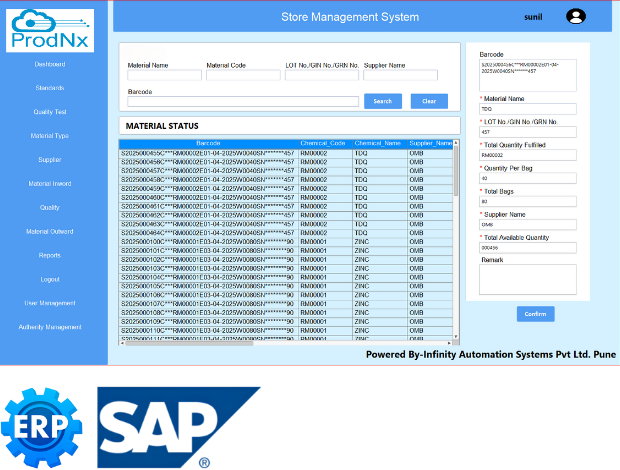

Store management system

- Smart Inventory Control: Real-time tracking of raw materials and finished goods

- FIFO with Barcode: Automated scanning and stock updates for efficient operations

- Automated Reordering: Stock alerts and auto-replenishment when inventory levels fall below defined thresholds

- ERP / SAP Connectivity: Fully compatible with centralized data management systems

ProdNx IT Platform

All our systems are controlled and monitored through ProdNx, a powerful IT platform designed for data recording, real-time reporting, and advanced plant management.

ProdNx Modules Include:

- ProdNx Store Management System

- ProdNx Recipe Management System

- ProdNx Small Chemical Management System

News from Infinity Automation

Trade fairs & Events

Contact us

Headoffice

Would you like to contact Infinity

Automation online?

Then use our online contact form!

.png)