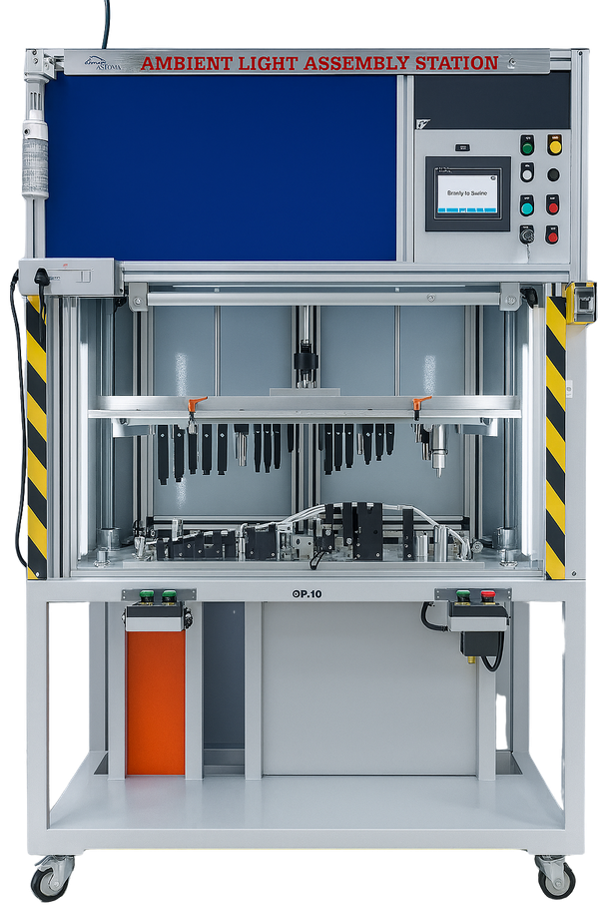

Ambient Light

The Ambient Light EOL Testing Machine performs precise functional and visual checks on automotive ambient Lightening using a light isolated chamber and high resolution camera. It features dual fixture testing, automated inspection, marketing, and Labeling with Lab View based real time monitoring. Loading/unloading is manual for flexibility.

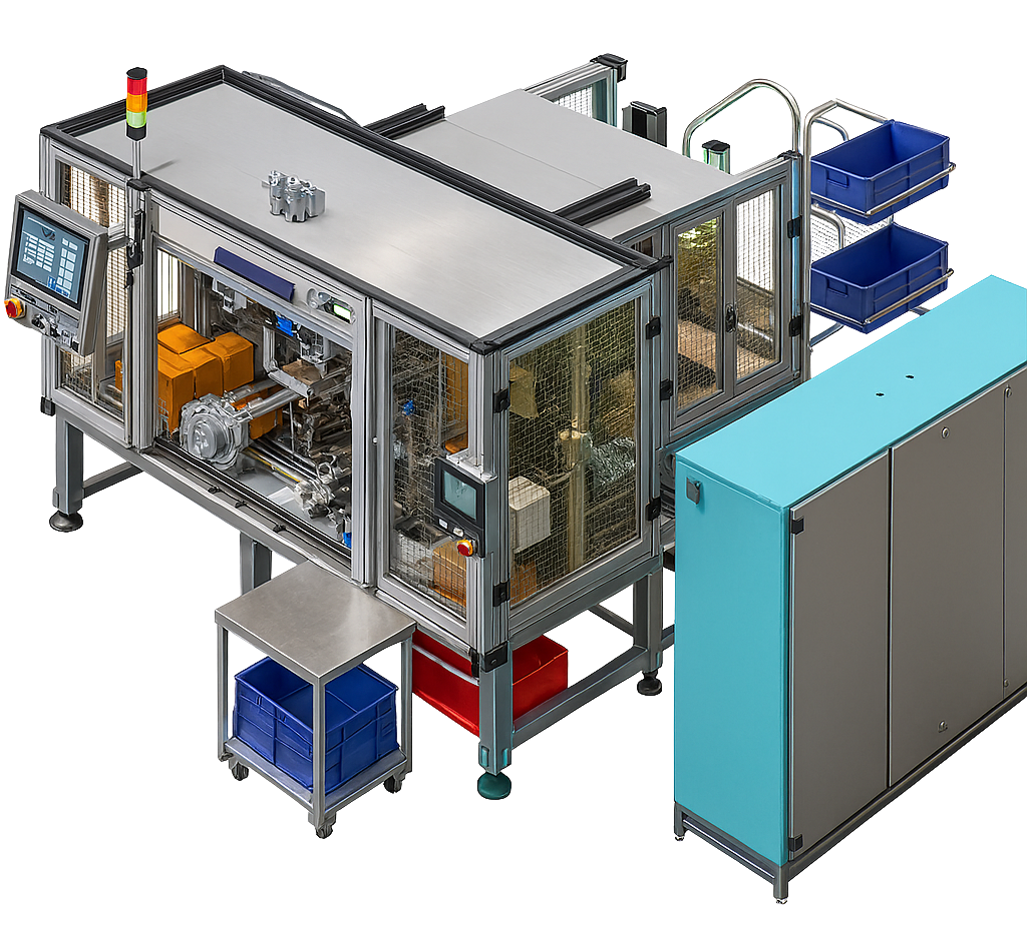

Evaporator Assembly

Our Evaporator Assembly Machine is a fully integrated solution for automated HVAC component production. It assembles tubes and fin matrices with high precision using servo and pneumatic systems.

Processes

- Auto Tube Dropping

- Servo Matrix Transfer

- Pneumatic Tempering Press

- Servo Back Compression

- Header & Tank Assembly

- Full safety fencing for operator protection

Number of Stations: 1 integrated station

Number of Operators: 2 operators required.

Cycle Time: 65 seconds per unit.

Bi-metal Clutch Testing

The Thermal Test Rig Station is a fully automated solution for testing bi-metallic clutches under controlled thermal conditions. It performs clutch freeness checks, thermal cycling (40°C–70°C+), and real-time pin length measurement using LVDT sensors. Integrated barcode tracking and data logging ensure traceability and quality.

Processes

- Freeness & pin sub-assembly testing

- Thermal expansion monitoring

- LVDT-based measurement

- Automated pin verification

- Barcode generation & data logging

News from Infinity Automation

Trade fairs & Events

Contact us

Headoffice

Would you like to contact Infinity

Automation online?

Then use our online contact form!

.png)