Chemical Batch Weighing

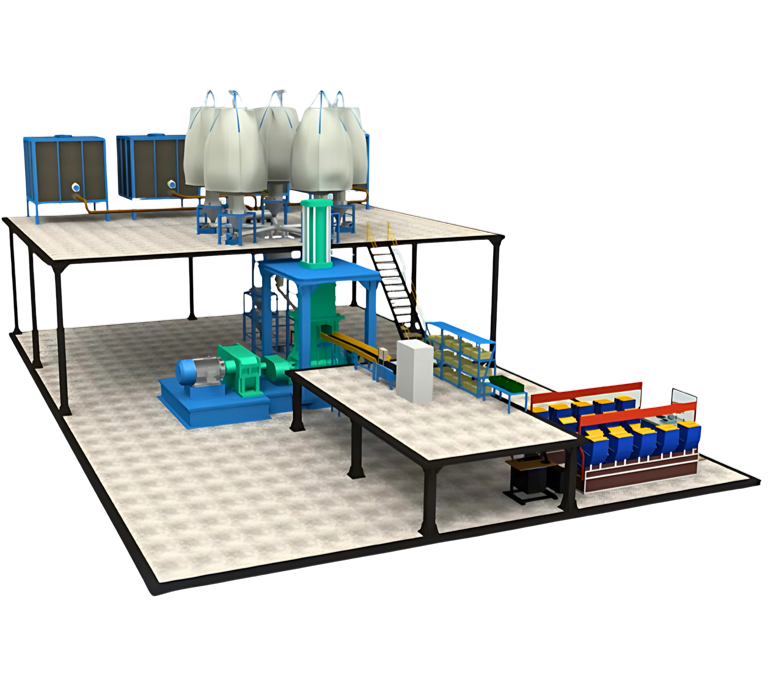

Infinity has developed an advanced closed-loop polymers weighing system designed to offer high precision and industry-leading features. The system is engineered for seamless integration, flexibility for weighing operations.

Process

- PLC HMI based system architecture Upto 10 mg accuracy

- Compatible for Scheduling of batches

- Capable of storing unlimited number of formulas/recipes

- Lot tracking & validation features FIFO based bins

- Compatible for ERP & SAP Standalone & central server based operation

Polymer Weighing

Infinity’s closed-loop system ensures precise, flexible, and integrated polymer weighing.

Process

- PLC-HMI based architecture with interlocks

- Weighing accuracy below 50 gm

- Customizable conveyors: take-off, checkweigher, and feeding

- Feeding conveyor usable standalone or with checkweigher

- Supports batch scheduling

Carbon Weighing

The Carbon Batching System is designed for dust-free, sealed operation, ensuring safe and accurate raw material handling. Materials are conveyed directly to the mixer using variable-speed screw conveyors for precise dosing.

Process

- Screw-based conveying with VFD control

- Maximum accuracy up to ±10g PLC-HMI control

- SCADA integration & batch scheduling

- Supports 50kg bags and jumbo bags

- Customizable design for optimal batch time and productivity

Oil Weighing

The Oil Weighing System enables precise and automated oil dispensing into mixers using a coarse-fine delivery method, ensuring clean and accurate dosing.

Process

- Auto dosing & sequencing for faster processing

- Accuracy up to ±10mg PLC-HMI control

- SCADA integration & batch scheduling

- Handles high/low viscosity liquids

- Heating provision for highly viscous oils

- Supports multi-oil injection with minimal cross-contamination

- Customizable for optimized batch time and productivity

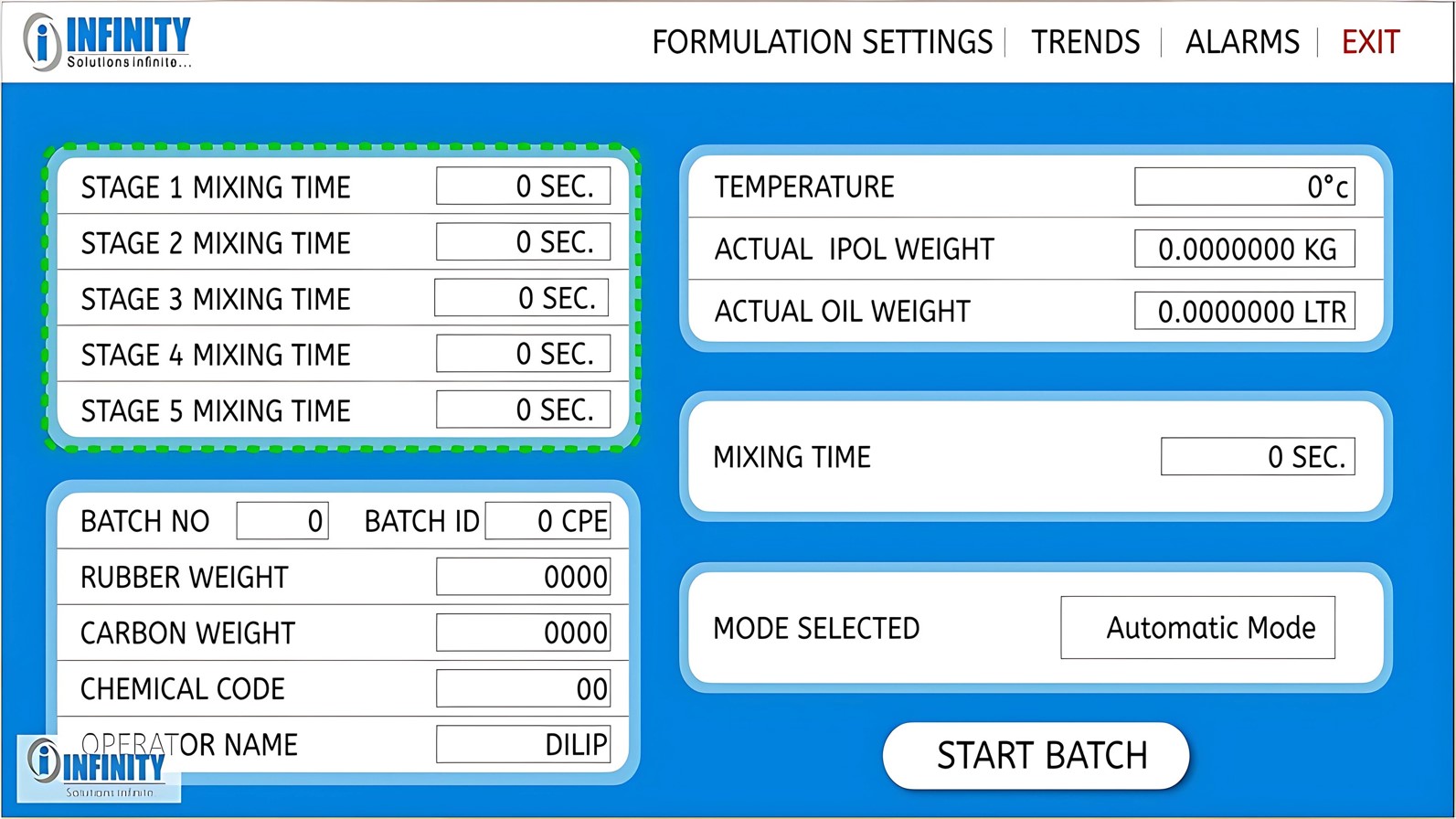

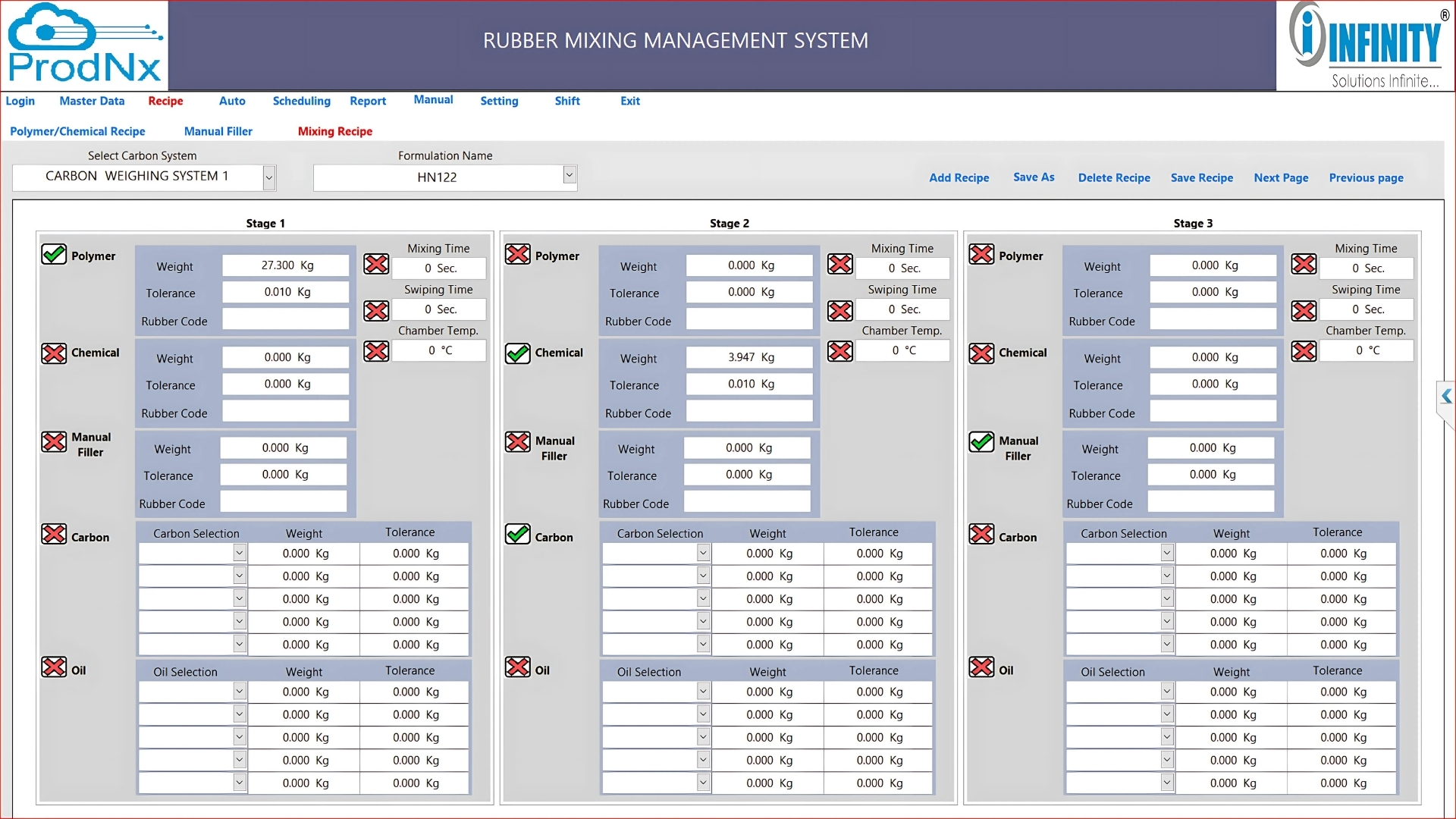

Kneader/Intermix Automation

- Recipe-based formulation

- Multi-stage mixing

- Centralized batch scheduling

- Chamber temperature analysis

- Automatic weighing & dispensing integration with oil weighing, polymer weighing, and carbon weighing systems

The Intermix Software manages the complete mixing process with advanced control and monitoring.

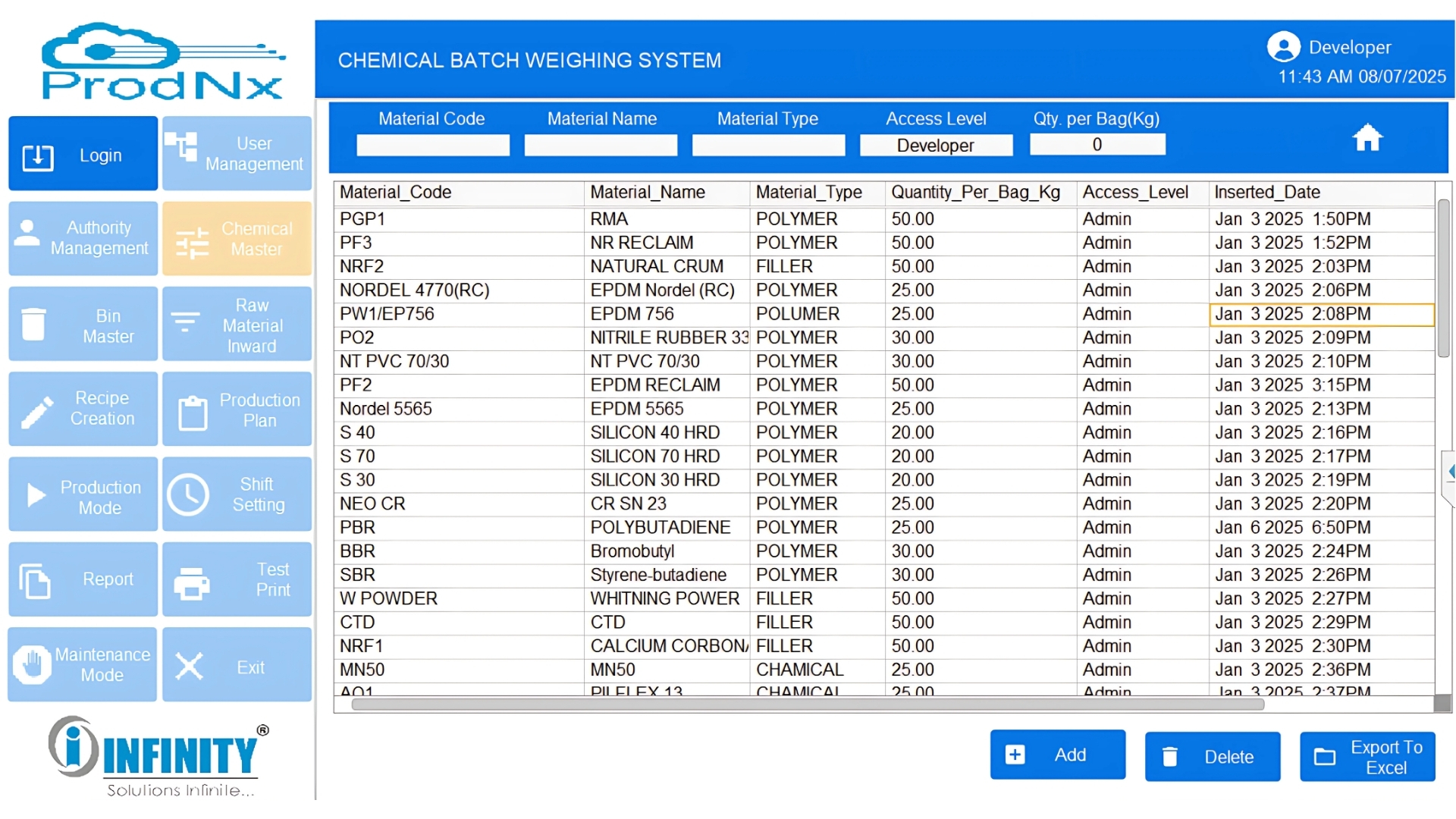

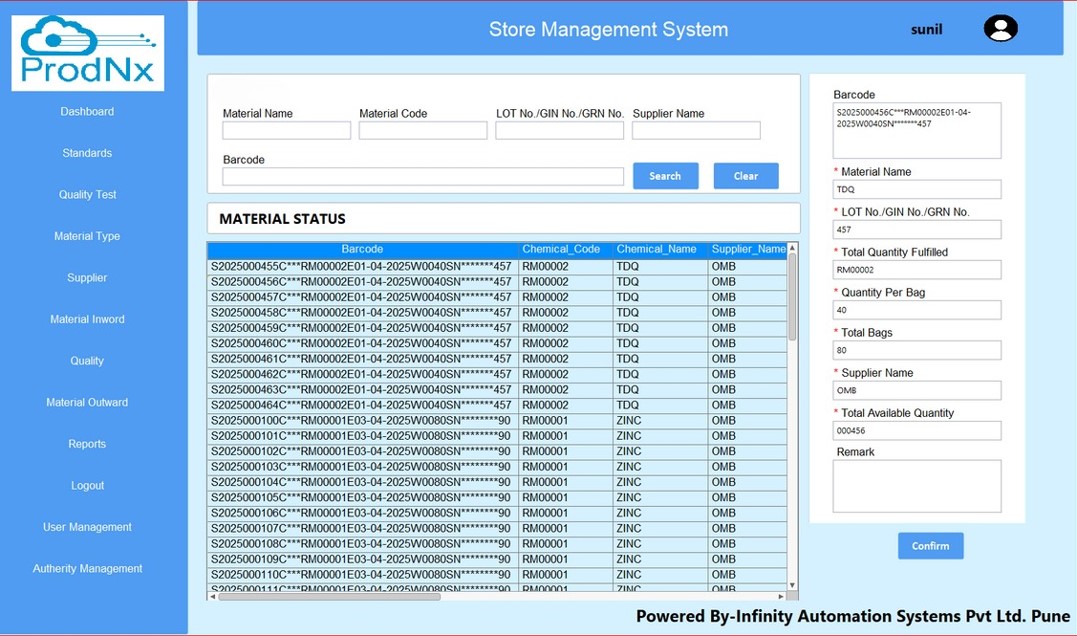

ProdNx IT Platform

All our systems are controlled and monitored through ProdNx, a powerful IT platform designed for data recording, real-time reporting, and advanced plant management. With ProdNx, every batch, recipe, and material movement is recorded, ensuring process transparency, regulatory compliance, and improved productivity.

- Smart Inventory Control: Real-time tracking of raw materials and finished goods.

- Barcode Integration: Automated scanning and stock updates for efficient operations.

- Automated Reordering: Stock alerts and auto-replenishment when levels fall below thresholds.

- Integrated Reporting: Detailed analytics on inventory usage and trends.

- ERP Connectivity: Fully compatible with centralized data management systems.

- ProdNx Store Management System: Real-time inventory tracking with barcode/RFID integration and automated reporting.

- ProdNx Recipe Management System: Digital recipe storage with version control and repeatable batch execution.

- ProdNx Small Chemical Management System: Intelligent weighing, dosing, and full traceability of micro-ingredients.

News from Infinity Automation

Trade fairs & Events

Contact us

Headoffice

Would you like to contact Infinity Automation online?

Then use our online contact form!

.png)